There is currently much discussion and much being written regarding two mounts - the HEQ-5 and EQ-6. Some things are true but some are incorrect. Clearly, equipment produced in such quantities may occasionally have some variations in manufacturing tolerances and in how well finished it is, which could be improved, but these problems can be dealt with.

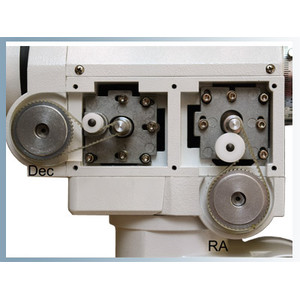

It is certainly not generally so. On the contrary! Both mounts are well-designed. The bronze worm wheel alone is mounted on its shaft via 3 large ball bearings and so is very solid. The stainless steel worm screws are of course mounted on 22x8x7 bearings on both sides. If problems occur, such as a slight irregularity in the tracking every 2 - 3 screw revolutions, then so be it. We will examine this in more detail later. The other end of the axle is centered and pre-loaded on taper-roller bearings. It runs fine. The EQ6 is distinguished from the HEQ 5 here only by its much larger RA taper-roller bearings and of course by its sturdier construction.

We provide the following special services for the HEQ-5 and EQ-6 mounts: Re-greasing and bearing replacement

Why re-grease?

One of the most common criticisms concerns the bearing grease used at the factory. The mount runs reasonably well on this for the first few years. But then the lubrication properties start to deteriorate. The mount becomes stiffer and this eventually leads to inaccuracies in the tracking and positioning. And of course the drives become more heavily loaded which eventually leads to increasing wear. That might sound somewhat alarming, but really it shouldn't be. Do you not replace the oil in your car every several thousand kilometers?

There too there are gears at work, and they do not have to run as precisely as those in the mounts. Of course mounts do not have service intervals but, even if the best grease is used, one should really replace it at around10 year intervals, depending on the amount of use.

Why exchange the bearings?

Another point to bear in mind is the bearings themselves. Of course a complete set of high quality bearings from SKF or FAG is a good investment. But is this always necessary? In most cases, probably not. One must also decide which bearings in the mount are most important here, - clearly the worm bearings. Here, an assembly error sometimes occurs at the factory, in that not just the linear play of the worm is adjusted for, but the play adjustment screw is so over-tightened that the bearing is rammed into the end-stop of the worm. That is unacceptable. If this is the case, then it is possible that, when the screw is rotated in its bearing by hand, a very noticeable regular increase in resistance occurs and then drops off again after passing the tight spot. The system is hence cyclically overloaded, which can lead to bearing damage.

However, this problem is often only noticeable with every 3rd turn of the screw. This is because the same position of the bearing balls relative to the outer ring of the bearing occurs after each 2-3 turns.

If this problem occurs, these four bearings should be replaced with new high quality bearings. These bearings are inexpensive and the system can be re-greased at the same time. The mount is then inspected once again, correctly adjusted and will then run silky smooth.